Environmental Protection and Recycling – a Challenge for Everyone

No matter which industry we take a closer look at: It is an issue everywhere - and of course, as a company that processes synthetic materials, we are aware that it affects us as a manufacturer of composite and plastic horseshoes just as much as the manufacturers of car or bicycle tires or shoes, for example. For the latter, some stores have collection containers with bonus programs on new purchases – a good option for properly disposing of used goods. Some clothing companies make garments from plastic collected from the sea. Good compromises have therefore already been found in many areas. Unfortunately, it is more difficult to solve the recycling challenges in our sector. Due to the current situation and the fact that we are frequently asked such questions by our customers, we would like to take a closer look at this topic.

Useful Information About Recycling Synthetic and Composite Horseshoes

Resource-Saving Regranulate

Many of our customers already know that the use of resource-saving regranulate is nothing new for us. It started with accessories such as wedges and for a few years now we have also been making horseshoes from regranulate. BUT: Unfortunately, it's not as easy as you might think.

The plastic to be regranulated must be...

- completely clean,

- free from foreign particles ,

- and absolutely sorted by type.

All of this can be implemented in our production: The sprues produced during injection molding are collected by type (i.e. separated into Extra and Standard) and then regranulated by a partner in Germany. However, this is a major challenge when it comes to used horseshoes.

Return and Cleaning of Used Horseshoes

The old horseshoes would have to be washed for regranulation; all foreign particles such as small stones and also the metal core (in the case of composite horseshoes) would have to be removed. This requires a lot of manual work, large quantities of water, cleaning agents and ultimately energy.

In addition, alternative hoof protection is still a small market segment. A centralized collection system, such as for shoes, would still be difficult to implement.

The return shipment of used horseshoes would in turn consume many resources. In our opinion, all in all – at the present time – this would unfortunately be a recycling process that would do more harm than good to our environment.

Unmixed Regranulation - Sorted by Type

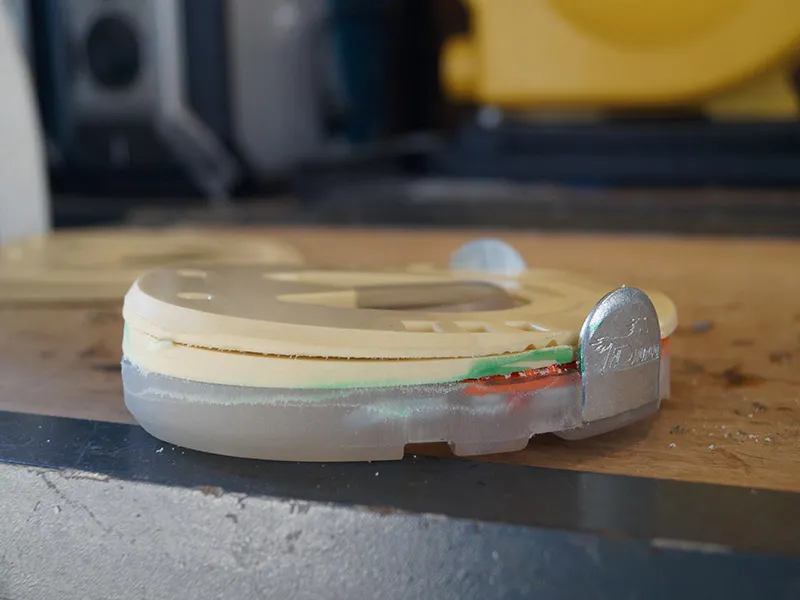

Even if there were a solution for cleaning and centralized collection, the challenge of sorting and regranulating would still remain. The most important aspects of our horseshoes are shock absorption , grip or slip behavior, and abrasion resistance , all of which are closely related to the plastic used. A mix of different plastics would always be a risky surprise package in terms of these aspects. But even with unmixed regranulate, which has been sorted by type, we have found that many small details in the regranulation process are important. For example, the horseshoes with yellow and blue knob arrays made from regranulate generally perform better today than the first attempts (the pink and black ones) did.

Our Measures within the Company

This means that, unfortunately, we do not yet have an optimal solution for recycling. However, this does not mean that environmental protection, resource conservation and a generally sustainable approach to our planet are not part of our agenda! We try to find the best possible compromise between economic efficiency and environmental protection in all areas.

- The sprues resulting from production are regranulated and processed as regranulate into new products.

- The so-called Duplo “dummies” that are created when installing a new tool are regranulated or used for the practice kits.

- Used packaging materials are processed into filling material using a cardboard shredder.

- Thanks to electronic data archiving, we reduce our consumption of paper and toner. We take the empty print cartridges to the Caritas collection; this supports charitable causes and the environment at the same time.

- Our production facility is equipped with a photovoltaic system so that we can supply our production entirely with solar energy - at least when the weather conditions are right.

- Some of our company vehicles have already been replaced by electric vehicles.

- With the Schmutzer farm near our production site, we support a regional project that is dedicated to sustainable agriculture with a holistic approach.

In addition to all these small steps, our centralized production in the Bavarian Forest in Germany is one of the biggest contributions to environmental protection. The fact that all work steps, from toolmaking and laser cutting of the metal cores to injection molding and storage, except for galvanization , take place on site means that unnecessary international transport routes are avoided.

Of course, we also try to keep all supply chains for the raw materials for our horseshoes as short as possible.

We are aware that we must never stand still when it comes to protecting our environment, just as we must never stop developing our products. We will therefore continue to work on finding a good and more environmentally friendly solution to these challenges.

Until then, we will continue with our small measures - because every contribution that each and every one of us makes, no matter how small, contributes to environmental protection and resource conservation on the whole.

Products Made from Recycled Plastic

First and foremost, our horseshoes made from regranulate should be mentioned here. These recycled plastic horseshoes are also available in two different hardness levels.

Various accessory products, such as our wedges for adjusting the hoof angle, are also made from recycled plastic, the so-called regranulate.

But not only us – other well-known manufacturers in our industry are also taking action. For example, there is a hoof stand by Blacksmith with a base made from recycled material.