Composite Horseshoes in Show Jumping and Eventing

Show Jumping, Eventing and Cross Country are demanding disciplines that require a lot from both horse and rider. High speed, various obstacles, and tight turns demand utmost concentration and precision.

With such demands, the requirements for the horseshoe are correspondingly high. In show jumping, the horseshoe must provide sufficient grip to prevent slipping or even falling when landing, and it must be sturdy enough to withstand the sometimes extreme stresses. Ideally, the shoe has stud holes that allow for regulary screwing in and out the horse cleats. This makes it possible to remove the cleats during rest periods to relieve the tendons and ligaments of the horse and to reduce the risk of injury in the herd.

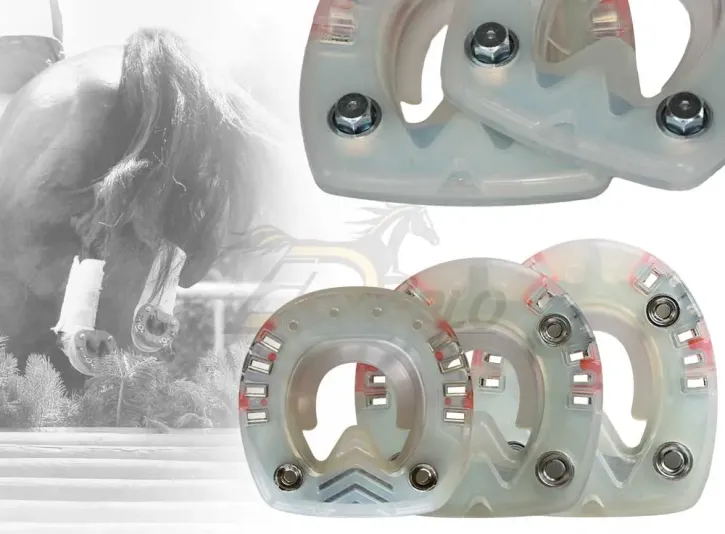

Our response to these requirements is our Jumper , a clipped straight bar horseshoe with integrated stud holes.

The sturdy crossbar of the Straight Bar horseshoe provides additional stability and is particularly resistant to twisting. Especially in show jumping, this extra stability can be beneficial to ensure that the horseshoe withstands the extreme stresses.

The quarter clips help prevent the horseshoe twisting or shifting on the hoof during regular shoeing periods. This is particularly important during landings and tight turns in the course in disciplines like show jumping or eventing.

The stud holes of the 'Jumper' are suitable for regularly screwing in and out the cleats. This allows the cleats to be easily removed after training or competition, preserving the locomotor system of the show jumping horse.

The special feature of this horseshoe is the shock-absorbing effect of the plastic coating. Especially in show jumping, eventing, or during hunting, high stresses affect the locomotor system of the jumping horse.

The Structure of a Composite Horseshoe

As the name suggests, the 'Jumper' horseshoe was originally developed for show jumping; however, the shoe has also found its fans among eventing and hunting riders.

We would appreciate it if you could take a few minutes to watch our animation video on the structure of the composite horseshoes . The video illustrates the interaction between sturdy metal and shock-absorbing plastic on the horse's hoof.

Clipped Straight Bar Shoe with Stud Holes — Photos

The Jumper is suitable as a horseshoe for show jumping horses, among others.

The Jumper is also commonly used in eventing.

Another application of this horseshoe is in equine driving sports.

Both the round and oval shapes of our Jumper horseshoe are equipped with four stud holes integrated into the metal core. The Jumper is available only in the slighly softer Standard material.

The STS version of our Jumper horseshoe features a slightly straightened toe area and only two stud holes. The quarter clips of the STS version are placed a little bit further towards the heels compared to the other shapes.

Among our Heavy Duty Shoes , there is a model similar to the Jumper — the Traction . The HDS Traction is available up to size 198mm and also features four stud holes.

The Jumper is suitable for regularly screwing in and out the horse cleats. You can find suitable cleats in the 'Anti-Skid Protection' category in our shop.

To seal the stud holes in the horseshoe, you can use our plastic Closure plug .

If you prefer not to use plastic closure plugs, there is a metal alternative available.

Application and Safety Instructions for Straight Bar Shoes with Stud Holes — Video

Our goal is to support show jumping horses as effectively as possible with our horseshoes and the appropriate cleats. Disciplines like jumping and eventing entail certain risks, and no matter how good the shoe may be, it's always possible for a horse to slip during landing or in tight turns. Therefore, always pay attention to a speed adapted to the ground surface.

Please refer to our safety instructions, which are directed not only to the farrier during shoeing but also to the rider and horse owner during the shoeing period. Thanks to the soft material and rounded edges, the risk of injury with a shoe with a plastic coating is lower in the herd. However, the use of cleats always carries additional risks. One of the great advantages of the 'Jumper' horseshoe is that the cleats can be screwed in or out as needed.

Shoeing Instruction

In our video tutorial , Stephan Becker explains the general application of our composite horseshoes. The adjustment of the shoe to the horse's hoof and the correct riveting are two of the most important aspects — especially when the shoe is exposed to high stress, as in show jumping and tight turns in the course.

Please do not grind down to the metal core and always keep the position of the stud holes and the straight bar in mind during all adjustments to the horseshoe.

The Jumper is typically used as a nail-on shoe. However, we have also heard from customers who have successfully used the Jumper as a glue-on shoe. From our perspective, this cannot be generalized, as we believe that especially in show jumping, a lot depends on the individual movement of the horse and the difficulty level of the obstacles. If you have made some experiences with the Jumper yourself, we would appreciate it if you would leave us a testimonial. This will help us and other show jumpers find their ideal horseshoe.

Modifying the Jumper Shoe

Due to the sturdy crossbar, the metal core of the Jumper — just like a conventional straight bar horseshoe — is less easy to adjust. However, thanks to our extensive range of sizes and shapes, there should be a suitable horseshoe for your horse.

The Jumper is available in the following sizes:

- round shape — typically for the front hooves — from size 114mm to 170mm

- oval shape — typically for the hind hooves — from size 114mm to 166mm

- STS-shape — with a slightly straightened toe area — from size 102mm to 154mm

For those dealing with larger hooves, we offer the 'Traction' model from our HDS range, which is available up to size 198mm.

If you're unsure about the correct size, feel free to use our template; available at FAQ → Sizes and Shapes.

Even with a straight bar horseshoe like the Jumper, it's possible to grind a toe direction or modify the open sole area into a closed sole area using our modification accessories.

We generally advise against using our Extensions to change the width or length of the horseshoe, as in these cases, the subsequent position of the stud holes and the straight bar may no longer be optimal, potentially exerting localized pressure on the wrong areas of the hoof.

Using Cleats During Extreme Stresses

Show jumping and eventing usually require higher cleats. The forces exerted on the shoe are enormous, so the stud hole must have a secure fit in the metal core. For optimal stability, the Jumper features a solid straight bar. However, when using higher cleats, it's important that the cleat, especially on harder surfaces, is not used permanently. Removing the cleats after training or competition also reduces the risk of injuries in the herd situation.

Please consider both the ground conditions and the dynamics in herd situations with every use of horse cleats. The stud holes as well as the correct position of the cleats and the horseshoe on the hoof must be regularly checked. Further information can also be found in our safety instructions.

We have various shapes and heights of horse cleats in our range that are suitable for use with the Jumper. Depending on whether you want to use the horseshoe for show jumping, hunting or "just" for the best possible slip protection in extreme winter conditions, you will need different cleats.

Our Selection of Cleats Suitable for Straight Bar Horseshoes

| Hexagonal Cleat | Conical Cleat / 'Ice' Cleat | ||

|---|---|---|---|

| Images |  |

|

|

| Type of Thread | not self-tapping | self-tapping thread | self-tapping thread |

| Changing Cleats | possible | easy | easy |

| Height | 6mm, 8mm, 12mm | 8mm, 12mm | 12mm, 14mm |

| Effective Height | 3mm, 5mm, 9mm | 5mm, 9mm | 9mm, 11mm |

| Thread Size | M8 , M10, M12 | M8, M10, M12, M14 | M8, M10, M12 |

We advise against using higher cleats, as they can strain the horseshoe and the horse's health too much.

Thread Size Depends on Horseshoe Size

The thread size of our Straight Bar horseshoes varies depending on the shoe size. Please make sure to choose the correct cleats when placing your order!

| Horseshoe Size | Thread Size Round Shape Horseshoes (Toe/Heels) |

Thread Size Oval Shape Horseshoes (Toe/Heels) |

Thread Size STS-Shape (Heels) |

|---|---|---|---|

| 102mm | --- | --- | M8 |

| 106mm | --- | --- | M8 |

| 110mm | --- | --- | M8 |

| 114mm | M8/M10 | M8/M10 | M10 |

| 118mm | M8/M10 | M8/M10 | M10 |

| 122mm | M8/M10 | M8/M10 | M10 |

| 126mm | M8/M10 | M8/M10 | M10 |

| 130mm | M8/M10 | M8/M10 | M10 |

| 134mm | M8/M10 | M8/M10 | M10 |

| 138mm | M8/M10 | M8/M10 | M10 |

| 142mm | M10/M12 | M10/M12 | M10 |

| 146mm | M10/M12 | M10/M12 | M10 |

| 150mm | M10/M12 | M10/M12 | M10 |

| 154mm | M10/M12 | M10/M10 | M10 |

| 158mm | M10/M12 | M10/M10 | --- |

| 162mm | M10/M12 | M10/M10 | --- |

| 166mm | M10/M10 | M10/M10 | --- |

| 170mm | M10/M10 | --- | --- |

The Special Feature of the Stud Holes in the Jumper Shoe

The stud holes of this straight bar horseshoe are firmly integrated into the sturdy metal core. As a result, they can withstand extreme stresses for longer periods.

When screwed in, the stud sinks into the thread for about 3mm. That way, the first pitch of the screw thread won't be damaged even during abrasion and the thread will be easier to clean. Using the 8mm studs as an example, this means that the effective height is 5mm.

During times without stud use, we recommend protecting the stud hole with a closing plug.

Mounting and dismounting of the cleats

If you need to screw the cleats in and out regularly, we recommend our cleats with self-tapping threads. In principle, changing the cleats is of course also possible with cleats without self-tapping threads; however, it is usually faster with the self-tapping version.

For changing the cleats, you'll need (each in the appropriate size for the stud holes of your horseshoe):

- cleats in the desired height

- stud hole cleaner

- hex key

- metal closure plugs, masonry

drill bit

, and matching hex bit or

plastic closure plugs and a slot screwdriver, for example

After you've finished training, unscrew the cleat from the stud hole using the appropriate hex key.

If there is dirt in the stud hole, you can remove it using the appropriate thread cleaner.

Insert your closing plug. If you've opted for a plastic closure plug, simply press it firmly into the stud hole. For screwing in the metal version, you'll need the appropriate bit.

Product Specifications

| General Data and Delivery Information | |

|---|---|

| Model | Clipped Straight Bar Horseshoe with Stud Holes |

| Brand | Duplo |

| Manufactured in | Germany |

| Item Numbers | 200, 210, 370 |

| Packaging Unit | sold individually |

| Returns and Exchanges | Possible under certain conditions within 3 months within the European Union (EU). For returns from outside the EU, please contact our customer service. All details can be found under FAQ → Service & Conditions |

| Function and Application | |

|---|---|

| Function | (Alternative) hoof protection, shock absorption, reduce concussion on hard surfaces, weight distribution, support for the rear hoof sections, bearing surface, 'weight' horseshoe, grip, show jumping shoe, horseshoes for cleats |

| Riding Styles and Disciplines | among others: eventing, military, foxhunting, hunter jumping, show jumping, off-road driving, skijoring , driving |

| Horse Breeds | among others: Bavarian Warmblood, British Riding Pony, Budjonny, German Riding Horse, Riding Pony, German Sport Horse, Hanoverian, Holsteiner, Mecklenburg Warmblood, Oldenburg, Einsiedler, Swiss Warmblood, Trakehner, Westphalian, Baden-Württemberg, Zweibrücken Warmblood, Dutch Warmblood, Hungarian Sport Horse |

| Season / Hardness Level | Available in the slightly softer Standard hardness degree and can generally be used year-round. |

| Measurements, Shapes, Sizes, and Weight | |

|---|---|

| Available Shapes | round and STS (usually fits front hooves) / oval (usually fits hind hooves) |

| Size Determination | Based on hoof shape and the widest part of the hoof (after proper trimming), or, if

necessary,

the size of the previous steel shoes. Feel free to use our free template. |

| Sizes (=Width) |

|

| Size Intervals | in 4mm steps |

| Length | varies by size – for details please visit FAQ → Sizes and Shapes |

| Thickness | 15mm |

| Weight | depending on the size from 242g up to 757g |

| Material and Construction – Special Features | |

|---|---|

| Plastic Coating | The soft plastic coating has a shock-absorbing effect. The bar made of plastic material can improve the blood circulation of the hoof. |

| Frog Support | Sturdy frog support with a metal core (straight bar) in the rear area of the hoof — flexible frog support made of pure synthetic material in the region of the frog apex (see illustration above) |

| Sole Area | The open sole design offers breathability to the hoof

sole

and the frog

. The molded synthetic lip, acts like a debris guard. It helps to reduce the amount of snow and debris balling up . |

| Grip | For additional grip, you can use cleats and/or spikes. Always adjust riding speed according to the ground conditions, especially on slippery surfaces. |

| Knobs | The knobs are impressed into the weight-bearing surface of the hoof wall and help the

nail-on horseshoe keep its position on the hoof. When used as a cast or glue-on shoe, the knobs must be ground down before attaching the cast hooks / before plastic-welding the glue-on tabs to the shoe. |

| Metal Core | The metal core enhances durability and helps avoid unwanted pressure on the hoof. The sturdy straight bar ensures a more even distribution of pressure across the hoof, providing additional stability. |

| Nailing Slots | The shoe features 6 to 8 nailing slots integrated into the metal core, depending on

size.

The optimal nail size varies by hoof condition and size. You’ll find general recommendations in our shop under hoof nails. |

| Quarter Clips | Quarter clips make nailing easier and help prevent the horseshoe from twisting or slipping

during the regular shoeing period. Be careful to adjust the quarter clips to the hoof angle when shoeing. |

| Shoeing and Customization | |

|---|---|

| Application | nail-on shoe, glue-on shoe or cast shoe |

| Shoeing Instruction | can be found unter FAQ → Instructions |

| Therapy Shoe / Rehab | The model is also suitable for supportive use in the orthopedic and therapeutic field. We expressly point out that our products do not diagnose or cure any diseases and advise for any use with a therapeutic or orthopedic background to work closely with the hoof specialist or veterinarian on site. |

| Customization | Always fit the horseshoe individually to the hoof shape – use an angle grinder, belt

grinder,

hoof nippers, or toeing knife. Please refrain from grinding all the way down to the metal core.

Advanced modifications (at your own discretion) are possible: narrow, widen, lengthen the shoe or close the sole area; you may also bend or grind a Toe Rocker . We strongly advise against using the Extensions to widen or lengthen the horseshoe, as this can negatively affect the position of the solid straight bar and the stud holes and may lead to unwanted pressure on sensitive areas of the hoof. More info available under FAQ → Adjustment to the Hoof. |

| Accessories | among others Wolf Busch® glue-on tabs, Hoof Sole Protector , wedge , colored stripes, cast hooks, Spikes, cleats, closing plugs |

| Safety Instructions | |

|---|---|

| Safety Information | can be found unter FAQ → Safety Information |

| Safety Instructions as PDF Download | PDF Download |

| Risk of Injuries in Herds | minimized risk of injuries in herd situations and in case of irregular movements in comparison to a steel shoe or the sharp-edged border of a bare hoof - please also read our safety information; the quarter clips must be monitored. |

| Cleats | The use of cleats increases the risk of injuries. Please observe the additional information regarding stud use in our safety guidelines. |

| Stud Holes Embedded in the Metal Core | This horseshoe is suitable for the repeated insertion and removal of the cleats. Always protect the stud holes with stud blanks. |

FEI World Championships Aachen 2026 – World Equestrian Games

The organizers of the World Equestrian Games write on their website: “From August 11 to 23, 2026, the world of equestrian sports will return to the place where, in 2006, it experienced the greatest championship in its history.”

We’re especially excited to be there on-site with our team this time.

Twenty years ago, our alternative

horseshoes

were still in their early stages – we were just beginning to build the product

range

that today includes models like the Jumper: an alternative hoof protection solution for horses competing in

disciplines of the World Equestrian Games – jumping, dressage and para-dressage, eventing, driving, and

vaulting.

Our selection of composite horseshoes and accessories – both for our own horseshoes and for traditional steel shoes – offers a suitable hoof protection option for (almost) every horse.

We’re looking forward to having many exciting conversations with visitors and participants this summer in Aachen – and we’re curious to hear your feedback on whether and how our horseshoes can support horses in the disciplines of the FEI World Championships.

If you’re participating in the World Equestrian Games yourself and are considering competing with alternative horseshoes, we’d be thrilled. To be safe, we kindly ask you to check the specific FEI regulations regarding approved hoof protection.

Photo Contest – FEI World Championships Aachen 2026 – World Equestrian Games

Join our photo contest and become our brand ambassador in Aachen. From all entries, the Duplo team will select the best photos. The selected photos will be presented on roll-ups and posters at our booth during the FEI World Championships 2026 in Aachen. For each photo displayed at the booth in Aachen, the sender will receive a Duplo voucher worth €250.

More information and the entry form can be found under Info → Photo Contest.

We look forward to your photos and wish you the best of luck!

Manufacturer in accordance with the Regulation (EU) 2023/988 on General Product Safety (GPSR)

Manufacturer in accordance with the Regulation (EU) 2023/988 on General Product Safety (GPSR)

Name: H. Frank Kunststofftechnik GmbHElectronic Address: info@duplo-frank.de

Physical Address: Vorderfreundorfer Straße 20

ZIP Code: DE-94143

City: Grainet

Country: Deutschland

Phone: +49 (0)8585/96926-0

Responsible Person in accordance with the Regulation (EU) 2023/988 on General Product Safety (GPSR)

Name: H. Frank Kunststofftechnik GmbHElectronic Address: info@duplo-frank.de

Physical Address: Vorderfreundorfer Straße 20

ZIP Code: DE-94143

City: Grainet

Country: Deutschland

Phone: +49 (0)8585/96926-0